The Turnkey solution with more than 50 years experience

Who are we?

Born, bred, and developed on Orapa soil, MTL is a 100 % Motswana company backed by the multinational Industrial services Group – RSC. MTL works hand in hand with site engineers, architects, and designers harnessing top world-class talent to deliver practical structural steel solutions and associated industrial services, enabling MTL to offer a one-stop solution and single point of accountability for your site rehabilitation and maintenance requirements.

Our Services

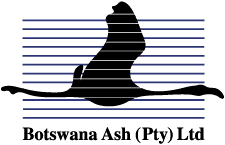

Steel Fabrication

MTL works hand in hand with site engineers, architects and designers harnessing top world class talent to deliver practical structural steel solutions and associated industrial services enabling MTL to offer a one stop solution and single point of accountability for your site rehabilitation and maintenance requirements. Boasting world class fabrication facilities in Francistown and Orapa MTL is an authentic Botswana business. These facilities enable MTL to meet the needs of the Botswana mining and energy industries. By combining extensive site steel fabrication and steel erection experience with world class safety and quality experience MTL offers a practical safe and high-quality deliverable by a 100 % locally owned company with exclusively local technical staff.

Abrasive Blasting

In Botswana, the MLT Triad Engineering is home to the biggest blasting yard. The most crucial stage of the corrosion protection process is surface preparation. For lack of a better analogy, “surface preparation” is to a coating system what a foundation is to a structure.

Corrosion Protection

The goal of corrosion prevention is to slow down the rate of oxidation, which will lead to reduced corrosion over time, increase the asset’s lifespan, ensure structural integrity, and reduce maintenance.

Industrial Painting

MLT specializes in the use of industrial paints in a variety of industrial, mining, oil and gas, petrochemical, and power generation settings. RSC has the experience to do high-quality work in a safe manner even in the most challenging environments, whether it involves working at heights or in small places.

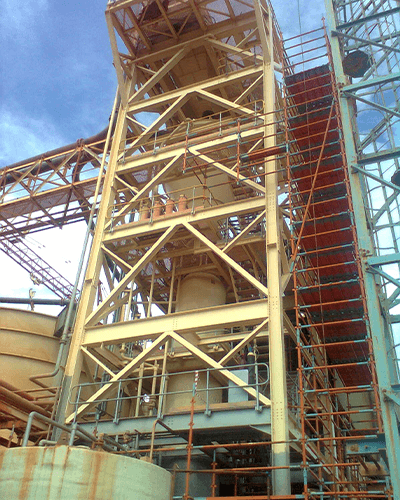

Scaffolding

The supply of scaffold was a sensible and organic service addition for the Group given the demands for access. Scaffolding has evolved into a key MTL service as a result of a rise in maintenance and project work for the petrochemical and power generating industries.

Concrete Rehabilitation

In the industrial setting, corrosion protection is essential for both concrete and steel structures. RSC has gained the knowledge necessary to perform new construction when necessary and give rehabilitation to corroded concrete structures.

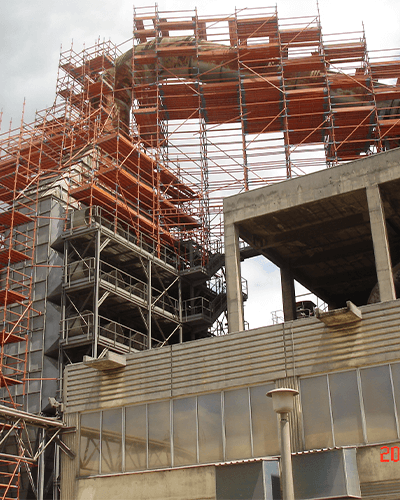

Secondary Containment & Acid Proof Linings

Design, supply, and application of acid proof linings are MTL’s areas of expertise. MTL can offer the most durable systems capable of withstanding the corrosive elements and thermal shock effects associated with the most aggressive acids, which are typically used for acid tanks, CIL areas, and bund containment zones.

Hot, Cold & Acoustic Insulation

MTL specializes in both thermal and acoustic insulation. Our Thermal Insulation Division provides both hot and cold insulation systems for sale and expert installation. Experience includes providing hot and cold solutions for the oil & gas, paper, sugar, petrochemical, mining, and power industries. Aluminum, stainless steel, and galvanized materials can all be created for cladding.

HP & UHP Cleaning

abrasive blasting is frequently used as a substitute because it is environmentally friendly. With operating pressures ranging from 68 bar to 2800 bar, RSC has the knowledge and tools necessary to accomplish HP & UHP Water Jetting.

Industrial Sheeting

RSC are specialists in the supply and installation of Sheeting to all forms of Industries. Our Sheeting crew are specialised Sheeting Applicators and can work off Scaffolding and do installations with Rope Access. We maintain a strict safety record with a low risk factor on all our projects.

Denso Steel Protection

Steelwork, tanks, and other plant components can benefit from a variety of anti-corrosion protection system solutions from MTL.

Fire Protection

MTL has received approval and training in the use of fireproofing products. This comprises fire-retardant compounds for cable racks, void/penetration sealants, and intumescent.

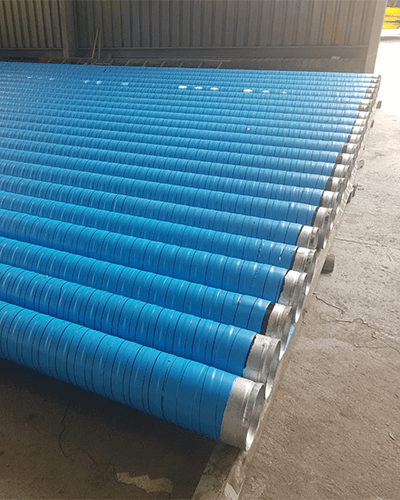

Rubber Lining

Using highly wear-resistant natural rubber, we provide wear and corrosion protection for chutes, pipelines, and tanks. This can be done at our workshop or on-site.

Rope Access

MTL specializes in using rope access techniques to get access to places that are inaccessible by scaffolding or other means.

Asbestos Removal

MTL is recognized as a registered asbestos contractor by the Department of Labor. We provide asbestos removal services that are both safe and in compliance with the law. Due to the historical widespread usage of asbestos and the knowledge that it poses a major health risk, an organized, safe approach to remove and isolate it is required.

Pigging

For purposes of inspection, desludging, and maintenance, MTL offers pipe pigging services. Pigging eliminates the need for line flushing, lowers product loss, and lessens the environmental effect of cleaning activities. Pigs make it possible to separate items in a pipeline, clean the inside of the line, analyze internal walls in real time, and record geometric data about pipes.

Our Projects

“Used Under License:”

Our Clients